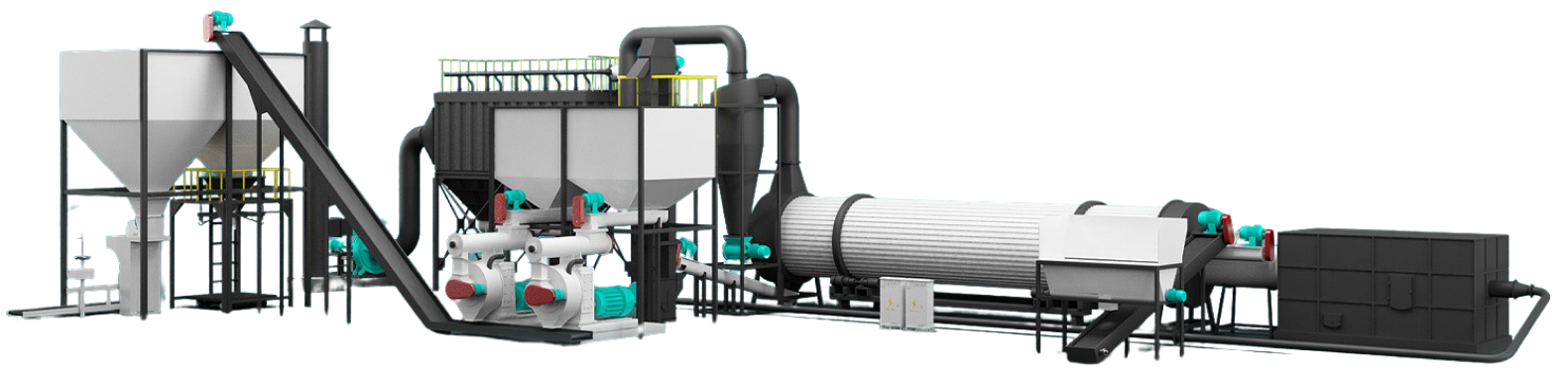

Manure Organic Fertilizer Dryer

Making Fule Pellets, Cork Wood, Corks, Wooden Pallets from agricultural wastes.

Biomass Rotary Dryer

Biomass dryer is an important part of biomass fuel production equipment. By drying biomass, they can be further pelletized to produce combustible biomass fuel. Or carbonized to produce biochar.

Capacity: 30-300 t/d

Dried Moisture: 12-15%(adjustable)

Raw material type: suitable for drying wood chips, sawdust, agro waste, MSW, RDF, straw, grass, bagasse, etc.

Applicable: widely used in chemical, agricultural, feed and fertilizer industries. And the drying of powder and granular materials with special requirements.

Introduction & Principle

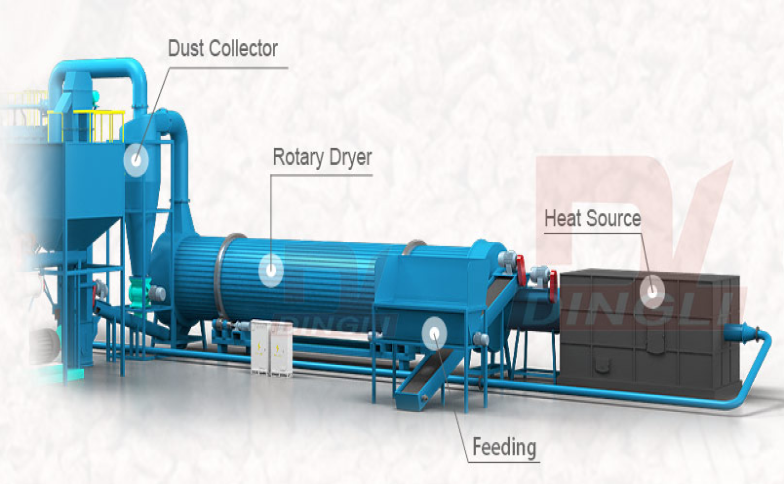

Biomass rotary dryer as known as three three-cylinder dryer. It is used in food, feed, fertilizer, chemical, pharmaceutical, and mining industries. According to the different requirements of the dryer. We have a different heat source.

For example, direct heating model hot blast stove, indirect hot blast stove, heat conduction oil, electric heating, steam, etc.

The rotary dryer is suitable for drying wood chips, sawdust, bamboo chips, wood powder, wood pieces, wood shavings, rice straw, wheat straw, corn straw, sorghum straw, maize silage, and potato vines, beanstalks, and so on.

The equipment has the advantages of large output, high efficiency and energy saving, small occupation area, energy-saving, and cost-saving.

- Raw materials

- Crushing

- Drying

- Pelletizing

- Cooling

- Packaging

Configuration

Biomass rotary dryer consists of a heating device, feeding device, transport device, rotary drum dryer, discharge device, dust extraction device, and other connecting parts.

Wet materials are continuously sent into the drum through a screw conveyor and then get separated and pushed by the high-speed hot flow. The moisture in wet materials is taken away in this process and then we get powder or pellet dry materials.

Parameters

| Model | Capacity (t/d) | Initial Moisture(%) | Final Moisture(%) | Drying Temperature(°C) | Total Power(Kw) | Cover Area (m²) |

|---|---|---|---|---|---|---|

| DLSG2010/3 | 62.5 | 60±5 | 12-15%(Adjustable) | 250±30°C | 78 | 8m×18m |

| DLSG2210/3 | 70.5 | 85 | 8m×18m | |||

| DLSG2510/3 | 83.5 | 110 | 10m×18m | |||

| DLSG2512/3 | 108.0 | 125 | 10m×22m | |||

| DLSG2912/3 | 120.0 | 135 | 10m×25m |

Introduction & Principle

Related Cases

Dingli Group has 20 years of R&D and production experience, 80+ export countries and regions, 1000+ successful projects. Looking forward to cooperation!

Introduction & Principle

-

Chat Online

-

Customized solutions

-

Factory production

-

Cargo inspection

-

Packaged shipment

-

Installation test

-

After-sales